Top page service

GOSHO

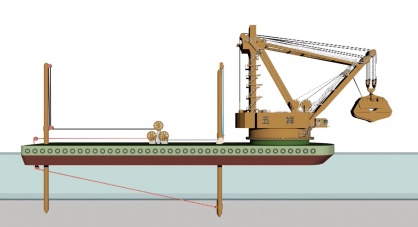

The world's largest grab dredger

GOSHO, The world's largest grab dredger

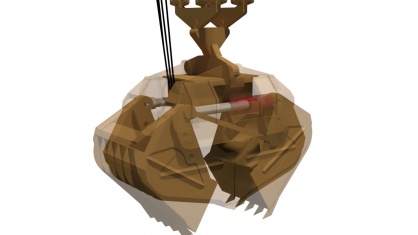

It is the world’s largest grab dredger “GOSHO” scooping enormous volume of soil from seabed in just a scoop with a roar. She is developed originally by KOJIMAGUMI as a work vessel. “Dredging” is like “a road work in the sea” creating channel by removing soil from the river or ports seabed. Recently deepening and expanding the channel has been required for large vessel’s safe voyage in world strategic ports and the degree of importance of “dredging” is getting higher than ever. Activate ports around the world with world’s top level dredging technology. That is our challenge!

Activate ports around the world with world's top level dredging technology. That is our challenge!